BAC Receives Office for Low Emission Vehicles (OLEV) Funding to Implement Nano Element ‘Niobium’ in BAC Mono, as Latest Proof of Concept R&D Project Begins

Briggs Automotive Company (BAC) has been awarded funding by OLEV through the Niche Vehicle Network (NVN) to undertake its latest Proof of Concept R&D project. BAC will use the grant to implement the use of nano element ‘Niobium’ in the structure of BAC Mono.

A soft metal, Niobium is a naturally occurring, readily available, sustainable element that is ductile, malleable and highly resistant to corrosion. It effectively enhances the mechanical properties (elongation, yield and tensile strength) of alloy metals and has therefore been used in a wide range of applications in the aerospace, architecture and energy sectors.

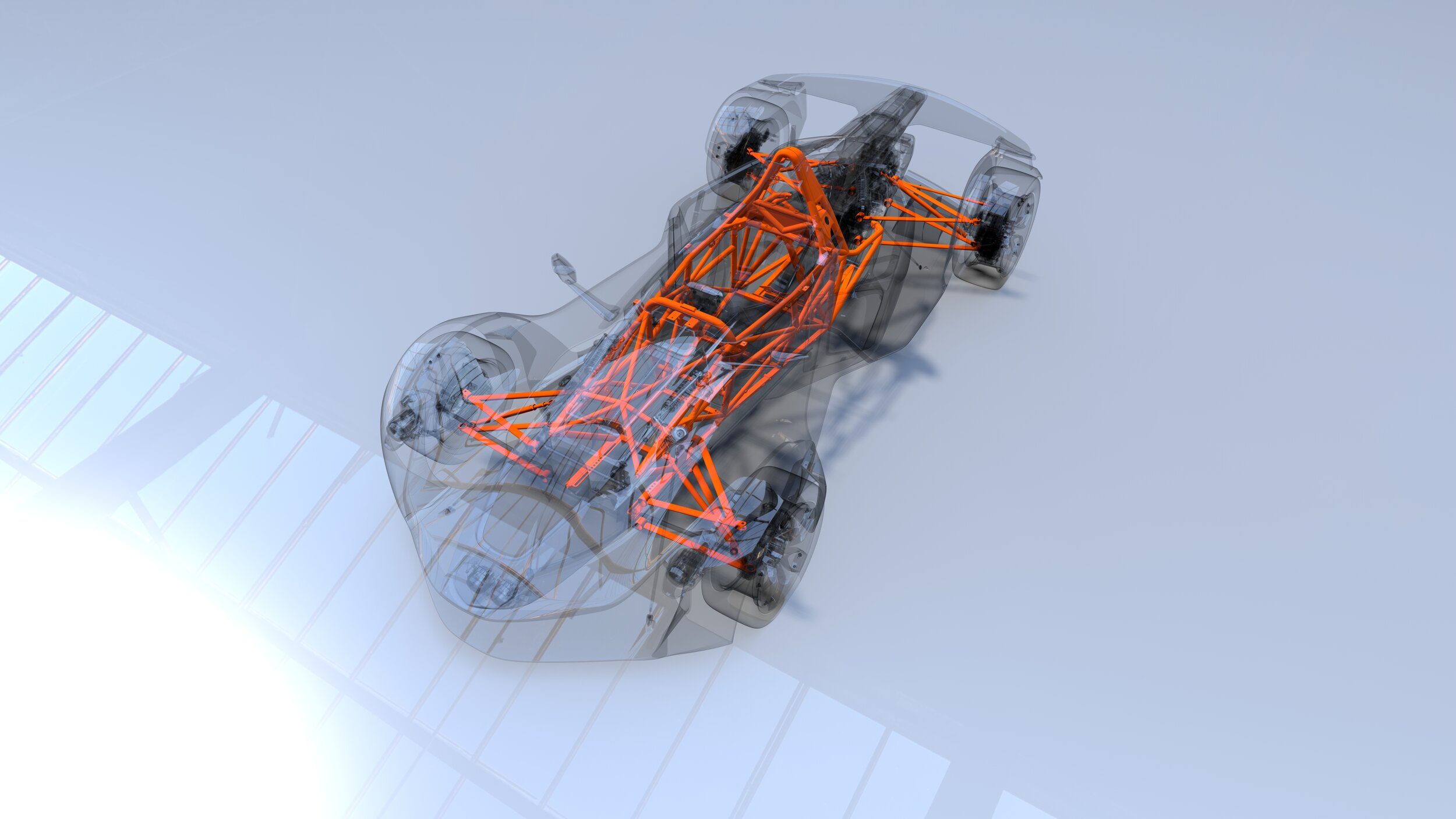

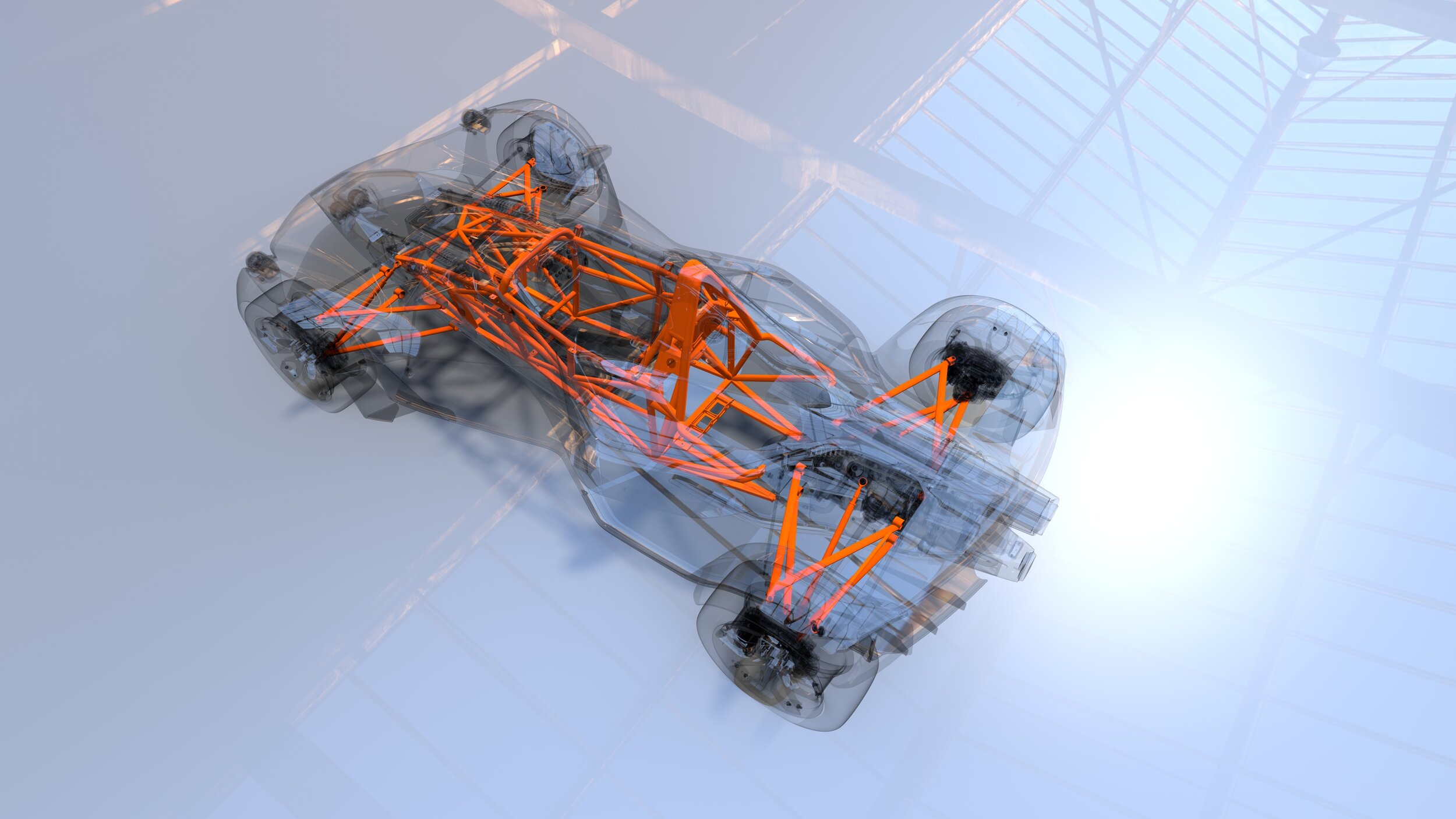

For BAC, Niobium will enhance the properties of the alloys used in the chassis and suspension systems of the Mono supercar. Using Niobium-enhanced alloys will mean less material will be needed to meet structural targets – resulting in lighter weight.

After the successful completion of an OLEV Feasibility Study into the use of Niobium for automotive lightweighting, BAC will now prove the concept by developing and producing structural prototype systems. If successful once again, the next stage of the project will be implementing Niobium into full production.

Despite Niobium’s use in the likes of jet engines, rockets and in building structures, BAC’s project will be the first time that the element has been used in the supercar sector, with the potential for the innovation to be used elsewhere in the industry (including with zero emission vehicles) upon completion.

The project is sponsored by CBMM, world leader in the production and commercialisation of niobium products with customers in over 40 countries. In the automotive sector, the Brazilian company is most recently known as Founding Supplier of Extreme E racing, a new racing series that caught attention of people like Lewis Hamilton, and for its involvement in Formula E.

BAC is no stranger to nano element technology and acting as an industry catalyst, having successfully completed R&D into the use of graphene-enhanced carbon composites in body panels on the Mono R. Similarly to Niobium, graphene enhances the structural properties of carbon fibre and warrants the need for less material use – making panels lighter.

The company’s obsession with lightweighting is all shaped around its primary goal of providing unrivalled, uncompromised performance on the road and track. Lighter weight means improvements in every area of the driving experience, including speed, agility and braking distances, resulting in faster lap times.

Neill Briggs, BAC Co-Founder and Director of Product Development, said: “We’re incredibly excited about our latest nano element R&D project and once again looking forward to putting BAC on the map as true pioneers of the automotive industry. BAC is all about revolutionary technology and pushing the boundaries of what’s possible, and using Niobium-enhanced structures is just another innovative way we’re finding crucial weight-saving solutions for the Mono supercar.”

17/9/20